English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

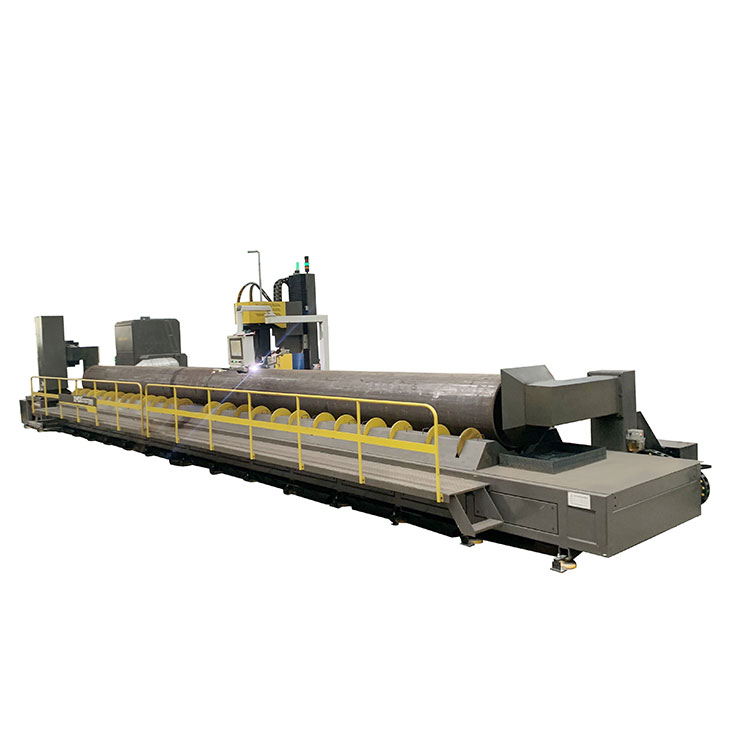

Pipe Cutting Machines With Roller Bed

JINFENG® is the professional China manufacturer and supplier of Pipe cutting machines with roller bed with affordable price. The Pipe cutting machines with roller bed are high performance plasma and oxy flame 3D cutting machine to execute the plasma cutting or oxy flame cutting on round pipe or tube.

Send Inquiry

PDF DownLoad

XMG

Pipe Cutting Machines With Roller Bed

For all the Pipe Cutting Machines With Roller Bed that manufactured by JINFENG WELDCUT will be delivered to End-user with 2 years warranty, and which are Equipped with a chuck to clamp the round pipe and turning the pipe during cutting, supporters for pipe. The plasma cutting torch and oxy flame cutting torch are mounted on the moving carriage which can move along the length of pipe . The machine supports all CAD-CAM interfaces as options. The XMG Pipe Cutting Machines With Roller Bed are the most advanced thermal cutting machine for pipe to increase the productivity for End-users from different industries.

Specifications

|

Model |

Round pipe diameter |

Max Length |

Max pipe Weight |

Remarks |

|

XMG 600 |

60-600mm |

12000mm |

5T |

2 line-rollers |

|

XMG 900 |

90-900mm |

12000mm |

5T |

2 line-rollers |

|

XMDG 1200 |

60-1220mm |

12000mm |

14T |

4 line-rollers |

|

XMDG 1420 |

60-1420mm |

12000mm |

16T |

4 line-rollers |

|

XFG1600 |

300-1600mm |

12000mm |

20T |

Chuck + 4 line-rollers |

Support Plasma cutting, Plasma marking, Inkjet marking, CAD-CAM software, dust extraction filters

Feature And Application

1.The XMG Pipe Cutting Machines With Roller Bed can offer high quality bevel cutting, hole cutting, vertical cutting for to reduce the mass works in next and make easy for welding connection in the next process.

2.The pipe cutting machine can be fully integration with the MES system and Allow remote control via team viewer for the engineers from manufacturer to easily carry out the remote diagnosis to solve the problems via internet without sending engineers to the working site.

3.The CNC software support the cutting operation and manual programming of parts based on the macros integrated in CNC. The CNC has a import interface forthe data file exported from TEKLA design software.

4.This XMG Pipe Cutting Machines With Roller Bed are widely used in Shipbuilding, shipyards, offshore, steel Construction, steel structure, piping, for the plasma cutting and oxy flame cutting of pipes to make stadiums, bridges, theme park, expo centers, airport, shopping malls, trusses, skids, frame, jackets, jack ups, support frame, pipelines etc.

By adding XMG Pipe Cutting Machines With Roller Bed to the production facility, the End-users from different industries can increase their production and reduce the labors a lot.

5.High efficiency: the pipe loading time is 1/5 of the chuck type pipe cutting machine (in the chuck type pipe cutting machine, the cutting time is about 1/3 for the whole cutting time cycle, the 2/3 time are preparation time before cutting)

Structure view

1.Dust absorbing -Optional

For the environment protection purpose, On both end of the machine installed a Dust absorbing devices to lead the plasma fume into dust filter. One side of the dust absorbing device is movable for different length of pipes.

2.Dust extraction filter

For the environment protection purpose, a dust extraction filter is equipped to the XMG Pipe Cutting Machines With Roller Bed . The filter is connected to the Dust absorbing devices via air ducting.

3.CNC control system

The CNC main control unit is an industrial controller, integrated with touch screen. With the hardware board card interpolation, the CNC has a reliable stability and easy and convenient wiring. With the standard G code, it is easy for operator to learn and operate on the machine. The CNC system supports 3 operating modes: Flame cutting, Plasma cutting and demonstration.

The freepipe software is a library of Macros, which is integrated in the software of CNC system and easy for operator for manual programming.

4.Roller bed

The roller bed consists of a table frame with many pieces of roller disks on top to support the pipe. For different size range of the pipe diameter, the pipe cutting machine will be designed to have 2 lines of rollers or 4 lines of rollers.

5.Cutting head on moving cart

The moving cart is moving in the length of the pipe to bring the cutting head to cover the whole length of pipe to realize the cutting on pipe with different length.

Pipe Cutting Machines With Roller Bed installed in User's factory.